So I finally decided to go ahead and get started on Cookie. I am using La-Doll and Premier clay, so I decided I would go ahead and follow Ryo Yoshida’s doll making methods from the Yoshida Style Ball Jointed Doll Making Guide. In the guide you cut your cores/armatures out of styrofoam based off of your drawings. I’ll get more to the method later, but in the picture above was my first attempt at carving the body core using the blue polystyrene insulation foam board. As you can see the core turned out terrible with way too many pock marks. Naturally I was displeased and I tried to figure out whether or not it was my tools that were the problem or whether you just shouldn’t carve out with the blue insulation foam. I’ve seen other people use the blue foam before to good effect, but it just wasn’t working for me with what tools I had so I decided to go out and get myself a sheet of the white styrofoam.

Nina gets a 25cm SB Obitsu – Deflopping Tutorial Inside

I decided with some left over Xmas money, to get my Nina a new obitsu. I really disliked her 27cm hard bust obitsu because the waist joint would constantly come apart, which meant I always had to worry about her loosing the bottom half of her body if I took her anywhere or showed her to friends. Also I felt like downsizing to the 25cm so she could work better with the dollhouse. I did of course design the dollhouse to even fit Taeyang, but having Pullip at 25cm makes the ceilings higher for her, and the re-ment kitchen works better for her as well. Anyway in the pic above you can see the height difference between the two bodies.

The rest of this posting is going to be behind a cut as it will be pic intensive, but I have a short obitsu deflopping tutorial inside, so read on if interested

Pullip’s House – Framing the Windows and Doors

Today I started framing the windows and doors that we cut out yesterday. I’ve begun by taking some 1/16th thick basswood that is 1/2 inch wide as my windows are, and using it make the casing. I had been considering using popsicle sticks, but the longest popsicle stick I could find at the craft store wouldn’t fit the lengths of most of my windows. Anyway you can see a progress pic up above. Since this is very small wood I used a crafter’s saw that is basically like a big X-Acto blade with a serrated edge to cut the pieces to size. I made sure that all pieces were cut to size and had a snug fit before I glued them into place. I think it is worth the extra effort to do this to your windows since it makes a nice clean straight edge, hides any errors you made, and also looks more authentic.

Pullip House Progress – Mini Window Cutting Tut

As you can see, we got all of the windows and the door cut out today! It’s finally starting to look less like shelves and more like a little house at this point. 🙂 As it were, it was quite easy to cut out the windows and doors after assembly, but before putting on the roof and base box. You could just turn the dollhouse to which side you wanted to work on and use the saber saw to cut out the window and door holes without need for setting up saw horses or anything. However I would recommend cutting out your door before assembly since the door comes flush to the floor and it can be tricky business to cut it out after being nailed and glued.

I’ve prepared a brief little tutorial on how we cut out the windows and doorway for anyone who is a beginner like me and needs some ideas. 🙂 So read on after the cut for the tutorial

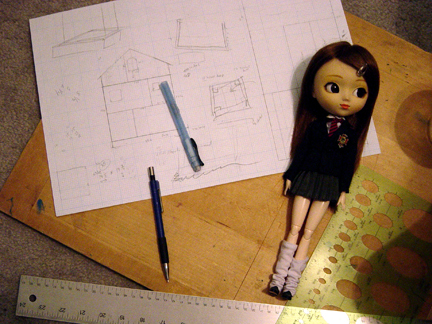

Pullip Dollhouse Project!

I had been wanting to build a dollhouse for my Pullip for some time, and I finally decided now was the time to jump in and start building. I’m looking forward to being able to buy cute re-ment to outfit the house, and also I shall be getting a new doll for Xmas, so now I will have a big house for my dollies to live in. It’s so exciting!

So, first things first, I had to come up with a plan. I really liked a Pottery Barn Kids dollhouse bookcase that was functional, yet also a playscale dollhouse, so I decided to use it as a base for my plans. I planned out everything on graph paper first so all of the measurements would easily transfer to the wood. Then you may also notice in the picture, I plotted out cutting plans on the size plywood I was intending to buy so not only could I get the most out of my wood, but also determine how much I would need to buy. In this case one full sheet and one half sheet was enough to get me started with all of the base construction.

During the planning stage I also used my doll quite a lot to determine the proper height for windows and also the sizes needed for windows and doors. By making to scale paper templates of your window frames and such you can get a cheap and visual idea for how things are going to pan out without spending money, or worse, making mistakes on your precious wood!

Now, I thought I would share some measurements with you, but these can really be variable determining the size of room you would like to have, but after measuring my Pullip and checking up on Taeyang’s height, I decided that I would make each floor 15 inches high, the attic room being the only exception. This will leave about 2 inches of space above Pullip’s head, and about 1 inch above Taeyang’s head. Now you may think to yourself, “well those are some low ceilings” and well, you are correct, but because I don’t want this project to get too tall or unwieldy, I decided I would compromise. Sure it would be fab to have tall ceilings, but I just don’t have the space! However to make things fun I will have the attic room which will have a high vaulted ceiling and I intend to put a dormer on one side of the roof which will add more space and also some interesting architecture. So, if you can’t have it all, at least you can have some of it. 😀

Getting back to the measurements though, I also decided to make the depth of the house 15 inches. This will allow you to put a Pullip sized bed vertically in any room and have it fit. Again, it is tight, but you should consider the space you have. Finally the last basic measurement for the house is that it is 3 feet wide. 3 feet allows for ample space for rooms. I prefer larger rooms, so I plan to only have two rooms per level and I will offset them so one room is larger than the other. For example my bathroom on the second level does not need to be very big, so by making it a 13 x 15 room, I can have a bedroom then on the same level that is almost 2 feet wide! Anyway I’ll be sure to post more measurements for windows and such the further I get into the house construction.

Continue reading behind the cut