I finally had a chance to give my Seven a face-up. It actually took 2 tries since I bungled the first iteration of this face-up and had to wipe it off. ><;; Anyway I just feel excited because I feel like a "leveled up" in the face-up department with my last two dolls (Zaoll Luv and LR Seven). I still have a long way to go I think, but I am starting to feel more confident. This face-up is also my first time painting the face of a boy doll. I was really nervous about attempting this, but as it turns out it's not much different from painting the girl's faces. I still need to get my Seven a proper wig, pair of eyes annnnd yeah, even a body. ><;; I'll be tackling the wig and eyes first since they are less costly and I'm still trying to hold onto my savings since I'm also still hoping for a Supia event with a boy re-release. Oh well, it gives me lots of things to look forward to in the end. I just hope I can get him a body before the end of the year.

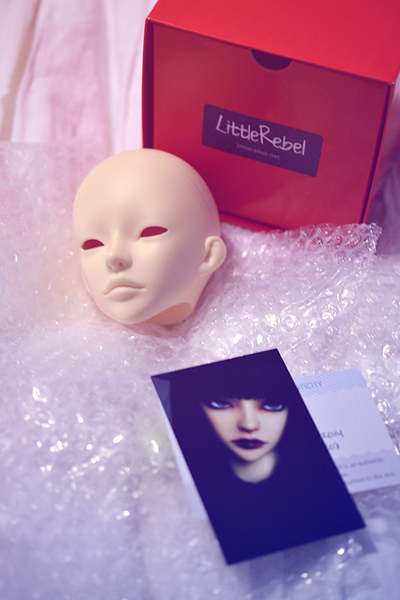

Little Rebel Seven Arrived!

I didn’t mention this earlier because I’ve just been so busy lately that I haven’t had the time to blog as much, but I managed to get in on the last Seven pre-order from Little Rebel earlier this month. He had been on my list of “do wants” for a while because he will be perfect for this character I have in mind that is a little bit sassy. XD Anyhow He arrived just this week and I thought I’d share some a couple arrival photos and some of my thoughts.

So, he arrived in a cute little red box all safe and sound with an authentication card. 🙂 My first impression on opening the package is that he looks even better in person! I can’t wait to try and give him a face-up but the weather here has been really poopy and rainy. Well that and I just had new flooring installed in my bedroom so I am also in the middle of trying to move all of my crap back into my bedroom along with keeping up with my comic and illustration work…so yeah…time, I need more of it. ^^;;

I wanted to see how the resin match was with my Dollstown elf girl in freshskin and I must say that the Seven head is a practically perfect match to Dollstown freshskin. My plan is to eventually get him a Dollstown 15 years boy body. I’m hoping I can accomplish that this year, but I am also saving a little stockpile of money in the hopes that Supia re-releases their boys again since I need a Zion to complete my “dream trio” of Mio, Seven and Zion. Of course I already have Mio, so I’m well on my way!

Ah, that reminds me…I’ve been ornery and I also ended up ordering a Buffdolls Unoa Zero headback, because yes, I’ve decided to take up the quest to assemble a Unoa Zero girl, ah hahaha…I’ll be keeping an eye out for Marion faceplates, and the Switch Humming Dolly Girl body will come with time, so really all I need to worry about there is getting the Marion faceplate.

Well that’s it for now! Back to work so I can afford all these dolls. *dies* XD

BJDs that look Asian.

Since it’s kind of difficult to search for BJDs that look Asian without most of the search results in google being about ABJDs on a whole and not necessarily ones that look particularly Asian, I decided to start a collection of images of Asian looking dolls on Pinterest. Each pin lists the sculpt, maker and size of the doll so you can easily find them on company websites. I’ve only just started my list with around 19 pins, but I plan to continue adding to it in the future, especially since right now I am of the mind to own a 60-65cm Asian looking male BJD to be a companion to my Mio. So, without further ado, here is the link to my “BJDs that look Asian” pinboard. 🙂

SD Room Box – Flooring

I’ve been meaning to blog about the room box flooring for a while now, but it’s been so busy around here and then my Taren arrived, heh. Anyway I’ve made quite a lot of progress on the floor so now I feel I can make a substantial process blog about it. So without further ado, here is how I went about making my room box floor.

So, materials wise I thought I would try using craft sticks, the jumbo variety that look like tongue depressors. With my craft saw and miter box I sawed off the rounded ends and then started gluing them to my plywood base.

Here is a progress pic of the gluing process. I also want to mention that you need to be sure to have some heavy objects to weigh down the planks of wood after you glue them because glue is wet and causes the wood to warp slightly before it dries. Weighing down your floor will keep things more uniform and save you from having wood planks punking up from the base in an unsightly manner. I suppose I should also mention that I did not cut all my wood and do a test layout of the whole floor. I worked two rows at a time and just made sure that none of the end seams lined up. I wanted the floor to look as close to a real hardwood floor as possible so I strafed all of the board ends and tried to make it as random as possible since real floors are random, well at least ours is.

So, you are definitely going to encounter problems when working with craft sticks, and the above picture is one of them. Because craft sticks are not uniform in size and some warp slightly you are going to get gaps between boards, especially when you are working at 1:3 scale. To solve this you will need to fill in the larger gaps with a wood filler.

I used the wood filler in the picture above to fill in my gaps. To be honest I was not all that impressed with this wood filler, and I probably would have selected something different, BUT this came to me free from my father’s workshop so I can’t complain too much. The thing about this wood filler is that it has tiny chips of wood in it and I would have preferred something with a much finer grain about it. Lastly I wanted to mention that I used one of my palette knives to apply the wood filler. It really makes filling in the gaps so much easier than using a regular old spackling knife since it’s more to scale.

And here’s where I have filled in some of the gaps with the wood filler.

The next step is to sand the whole floor. Sanding the floor will help you get rid of the slight bumpy irregular feeling your floor will have that just comes with using popsicle/craft sticks, not to mention that it will prime your floor to take a stain and/or varnish as well as smooth out your wood filler. I really think this is a necessary step if you are making a floor using craft sticks. I don’t care if you say you want it to be “rustic”, it’s not a “rustic” issue, it’s a craftsmanship issue, because even a good rustic floor has good craftsmanship. Haha…sorry for the lecture. XD

I opted not to stain my floor and decided to go straight to varnish because I just really like the light natural look of wood, plus I think it will be a nice compliment to the shabby beach theme I’m going for with the room box. I had been at a bit of a loss as to how to finish my floor though, because for one thing it’s winter where I live and using a polyurethane varnish inside the house, well I think you can imagine the smell and the headache afterwards. XP My other reservation to using a polyurethane varnish was that I have in the past had issues with some of the plastic or rubber soled doll shoes sticking to the flooring if left sitting on the flooring for any period of time. If not polyurethane varnish, your other options are to use linseed oil or a polyacrylic varnish, which is basically an acrylic varnish that washes up with water and is less smelly. As you can see from the pic above I opted to go with the polyacrylic varnish and I am currently waiting for my first coat to dry so I can gently sand it and then apply another coat.

This is my floor after one coat of the semi-gloss polyacrylic varnish. I ended up doing a really thin coat so it will probably take me 3-4 coats if I keep on like this with the ultra thin coats, but I think in the end it’s better to apply thin coats and build up to a nice semi-gloss. I chose semi-gloss because I didn’t want my floor to look too shiny since the floor looks a bit rustic and I would rather it look a bit more like a worn beach house floor than something high gloss and brand new.

So, now all that I have left is to sand, varnish, sand, varnish until I get the finish I want. I’ll be sure to post up a pic of the finished floor after this. I am getting excited because I am getting closer to having this room box finished! I am getting antsy to start working on some 1:3 scale furniture and props so I want to get it done within the next couple weeks!

SD/SD17 size Room Box Window

I’ve made a lot more progress on the room box, but I just haven’t had much time to blog. I wanted to share with you though my process for creating the pin hinged window. All of these pictures I was a bit lazy and just took them with my iphone camera since it was convenient, so please excuse the photo quality and also my ugly dry hands….They just get so dry and bleh whenever I’m doing woodworking. XP

Ok, so for the basic construction of the window, please refer to my last post where I showed how I laid out the frames, sashes and glued and painted them and etc… Here I will be focusing on the hinges and attaching the window to the house.

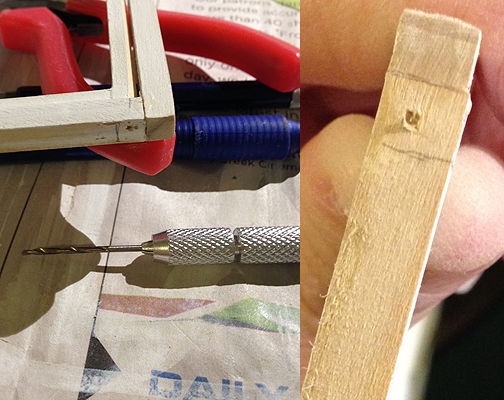

So the first thing I did was mark where the side of the window panel meets the bottom of the frame. I drew the box there so I knew where that wood board would be and then I marked with a dot about where I wanted to attempt my hinge. I decided to put the hinge a little off center and more towards the edge where I want the window to swing open. I made this decision by following this dollhouse pin hinge tutorial here: Pin Hinge Tutorial at about.com.

The tutorial at about.com has you using a hand drill for this next segment, but because I do not have a hand drill bit small enough for my liking I ended up using the hand drill here just to make an indentation into the wood to give a starting channel for my dremel which has a much smaller drill bit that is more suitable. Anyway the above shows you my hand drill tool and the starting channel for the dremel.

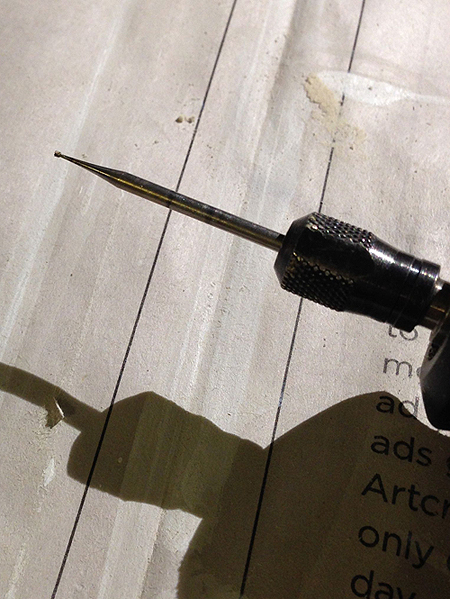

So this is the dremel drill bit that I used. It’s super tiny, but because it expands at the base, it is not possible to drill through the entire width/length of the wood pieces, but this is ok, because we will be using a dress makers pin for the hinge and you can gently force it through the wood the rest of the way.

Here is after I dremeled the hole and stuck the pin straight through to the other side. The next step is to line up the window inside the frame and pierce it with the needle.

Here I have perfectly aligned the window to the frame as I want it, and I re-inserted the pin through the hole to pierce the wood of the window itself. What this does is it gives you a small hole exactly where you need to drill the corresponding hole in the window.

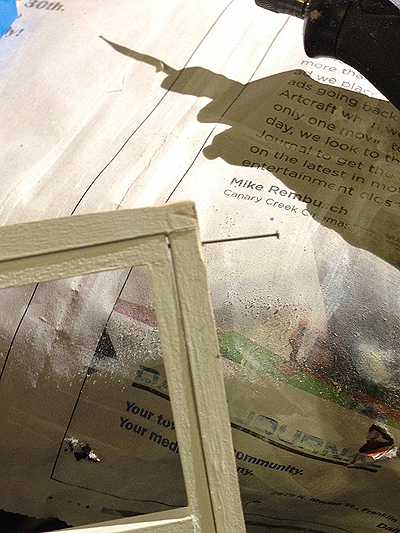

After you pierce/mark the window board, remove the pin again and dremel the hole. If need be start the channel again with the hand drill. I also want to point out that at this time, you need to bevel the side of the window that is facing the direction you want the window to open towards. I have decided I want my windows to open outward since it will be less likely to interfere with any future furniture arrangements. You can see my bevel in the picture above, but I will show another one below.

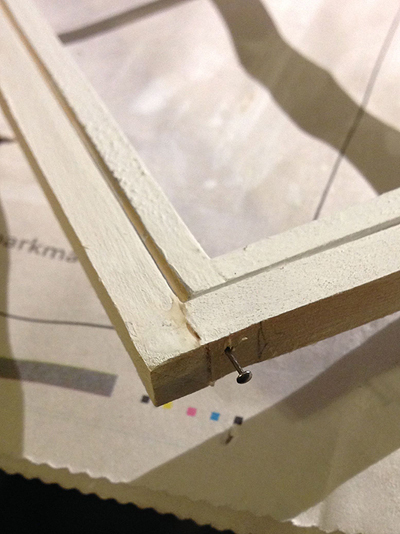

Here is a close-up of my bevel. Basically you will sand the corner off of the side the faces the direction you want the window to open…it will be about a 45 degree angle. You don’t need to do much and you can always touch up paint later. The reason why you need to do this is because your window won’t open if you don’t since it will get hung up on the squared corner of the wood. If you are having trouble grasping this section, then please refer to the tutorial I mentioned earlier as they explain it a little differently and it may make more sense to you. Oh and lastly you do not need to bevel where the two window panels meet in the middle, you only need to bevel the side which butts up against the window frame.

Lastly after doing your touch-up painting you will just reassemble your pin hinge. Here you can see my window snug in the frame with it’s bevel all ready to go. Now, since this is a larger scale window, you have two options to finish the pin here. You can leave the head on like I did and just gently press the pin all the way into the wood so that the head is flush with the bottom of the wood of the frame. If you do this, just take your time and be careful not to bend your pin! The other option which is discussed in the about.com tutorial is you can cut off the excess pin. If you cut off the excess pin though you will need to putty in the hole at the bottom so your pin does not fall out. Take care though not to accidentally fix your hinge in place. Personally I think it is easier to leave the head on, and considering this is for a 1/3rd scale doll roombox the tiny amount of pin head at the bottom won’t matter much in the long run when trying to fit your window into the window cut. That’s just my opinion though and you should do what is best for you and your project.

OK, so basically you will just need to lather, rinse and repeat the above steps to create pin hinges for the top and bottom of both sides. You will have 4 pin hinges total. Above is my finished product which I tested out to make sure everything was working fine before I went to glue it into place. Once you glue your window into the window cut you are pretty much stuck with it unless you want to remove the window to make changes, which is tough. So, get everything right the first time!

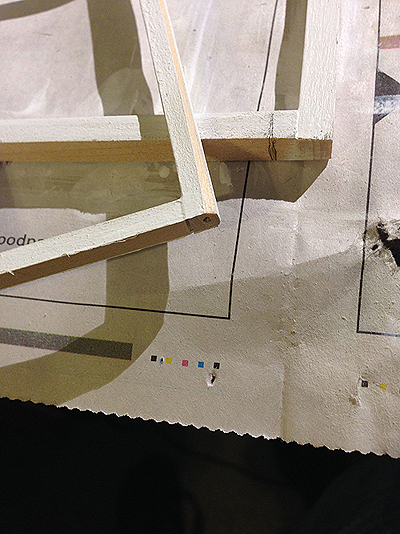

Ok here is the window being glued in. Be sure to have some little clamps handy if there is a section of window that is being testy and wants to come off center. I also tied my window panels together for safety since the pin hinges are delicate. Yes, please do keep in mind that the pin hinges using sewing pins is delicate at this scale. If you want something more durable for rugged play you may consider trying small finishing nails. Also, one more tip and that is to be sure during the whole process of creating the window that you are double checking the fit to the cut in the room box. It is very easy for things to become a little off, especially when gluing in all those sashes, so keep checking up on the fit so you don’t have any unhappy surprises at the end where the window doesn’t want to fit into the window cut without extensive sanding. If you keep checking the fit you can make minor adjustments here and there and save yourself a lot of tears and frustration.

I also wanted to point out here that making window cuts with the saber saw are never perfect. Here you can see one of the larger gaps between my wall and window frame. You can fill a little bit with glue at this point if you are concerned about stability or you have too many big gaps like this. Keep in mind though that you will be cover the window frame and part of the wall with your window trim anyway and the additional layer of wood on glue will also add stability and perhaps more importantly HIDE YOUR ERRORS!! hahahaha!

I have yet to trim my windows as I ended up getting started on the wood flooring right after this, but I will leave you with this picture that shoes the scale between the window and my Zaoll hybrid. It’s not a very good photo of the doll, but I guess that’s not important. So another thing to keep in mind, Zaoll is only 53cm tall. The current design is probably best for 60cm dolls give or take a centimeter. The 65cm boys will still be able to look out the window, but they will seem a bit overly tall. This is fine for my purposes though because the room is for my girl, and the scale will play up her shortness a little. I’ll be sure to pose the final touches with the trim later and perhaps later on tonight I might blog a bit more about laying down this flooring while the glue is drying yet again.